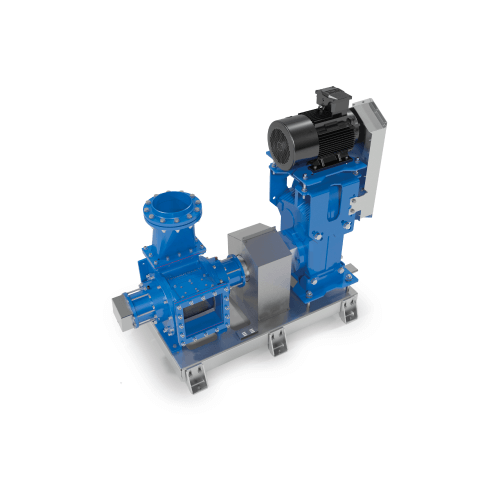

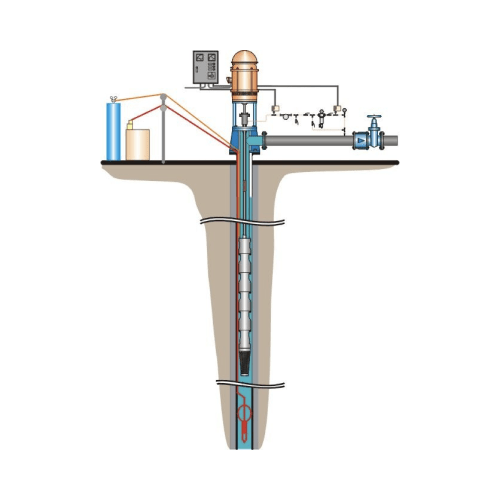

HD býr að áratuga reynslu í vali og hönnun borholudælna og djúpdælukerfa. Við val á búnaði er tekið mið af aðstæðum hverju sinni – svo sem dýpi niður á vatnsborð, afkastakröfum, hitastigi og efnisinnihaldi vökvans.

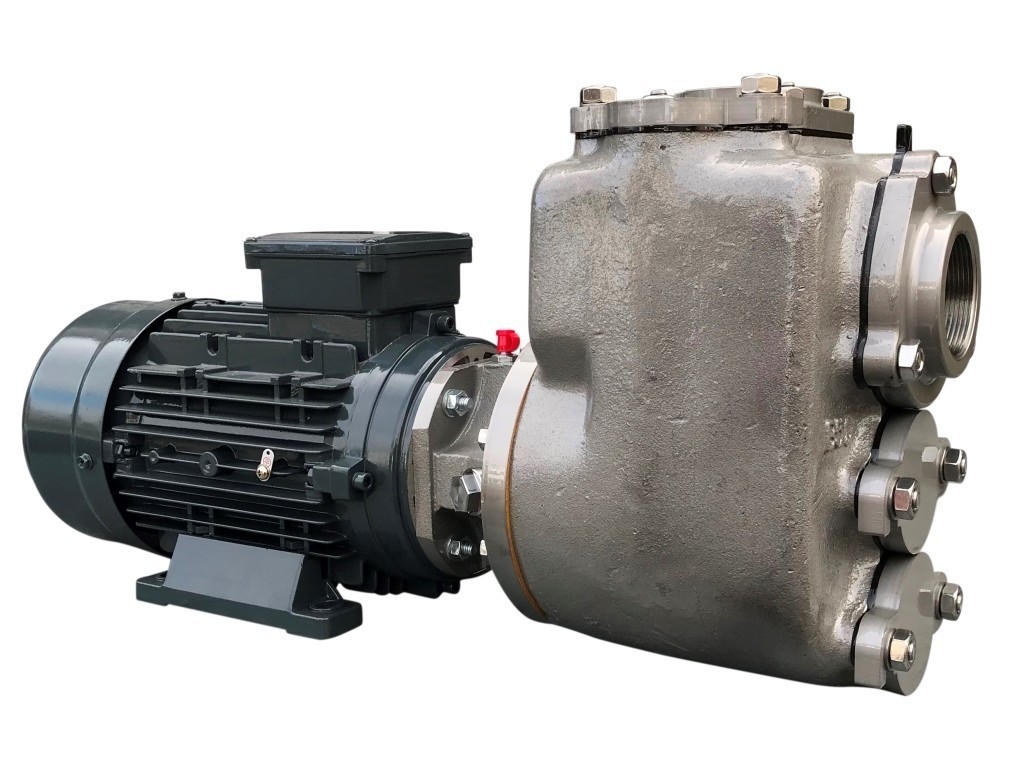

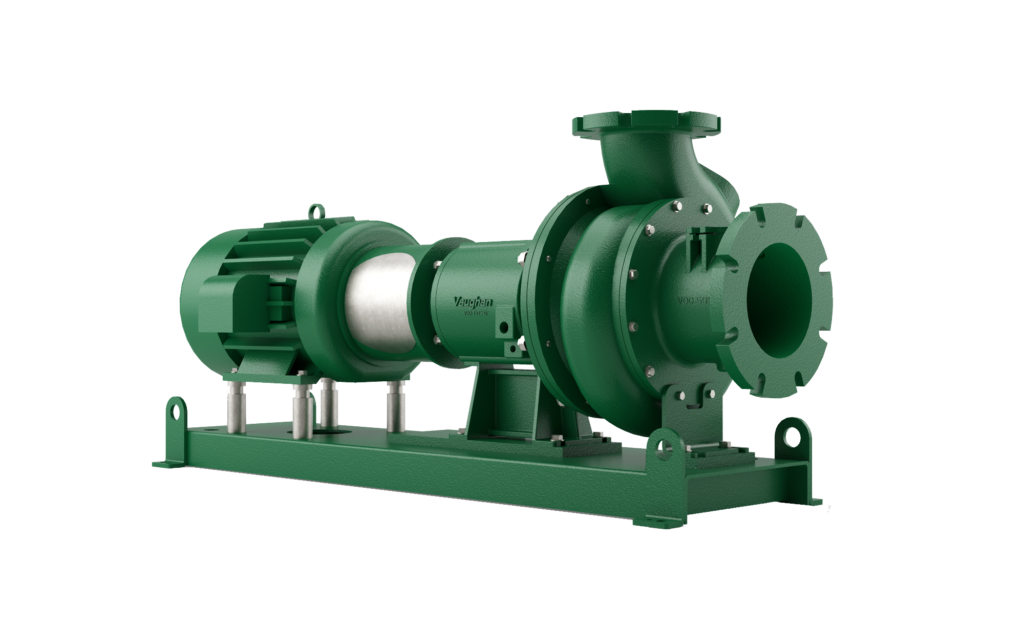

HD býður öxuldælur sem hafa reynst einstaklega áreiðanlegar, sérstaklega í hitaveitukerfum. Yfir 120 slíkar lausnir eru nú í daglegri notkun víðsvegar um landið.

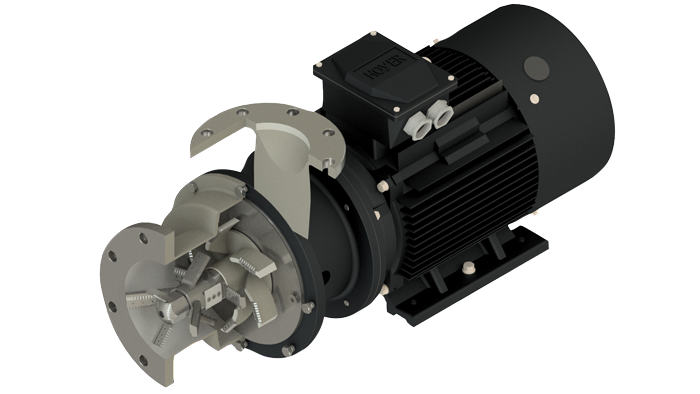

Við bjóðum einnig sambyggðar djúpdælur fyrir heitt og kalt vatn og jarðsjó – allt frá lausnum fyrir minni veitur upp í öflugar háspenntar dælur með mikla nýtni og nánast ótakmarkaða dýptarmöguleika.